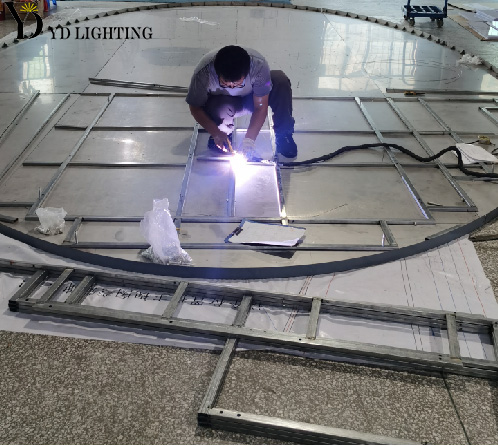

The process of hardware processing 1

In the hardware processing of lighting fixtures, first of all, suitable materials such as stainless steel, aluminum alloy, and copper should be carefully selected and strictly inspected to ensure that the materials meet the standards. Next, equipment such as laser cutting machines and CNC sawing machines are used to accurately cut and blank according to the design drawings. Then, forming treatments are carried out through processes such as stamping forming, bending processing, forging, or casting. After that, surface treatments like grinding and polishing, electroplating, and spraying are performed on the components to enhance their texture and performance. Finally, the processed hardware components are assembled with other components such as light sources and wires according to the process requirements, and comprehensive inspections of electrical performance, structural stability, etc. are completed. Only after passing all inspections can the products be packaged and launched on the market. The entire process is meticulous and rigorous, endowing the lighting fixtures with both practical functions and aesthetic beauty.

The process of hardware processing 3

The process of hardware processing 3

The process of hardware processing 2

The process of hardware processing 2

The process of hardware processing 1

The process of hardware processing 1