About Us

Modern Lighting Guide

Views : 308

Update time : 2025-10-09 15:43:00

Modern Lighting Guide

1. Materials

Iron: Strong, cheap but heavy; rusts untreated.

Copper: Warm, anti-corrosion but soft, pricey.

Aluminum: Light, versatile, anti-corrosion; good for custom designs.

Stainless Steel: Sleek, durable but heavy, costly.

2. Surface Finishes

Powder Coating: Cheap, tough, many colors.

Electroplating: Metallic sheen, better anti-corrosion.

Anodizing: Boosts hardness/color (great for aluminum).

Dyeing: For brand/decor needs.

3. Sizing

Check ceiling height, room size.

Choose: Main light (tasks) or ambient (atmosphere).

Avoid oversized/undersized fixtures.

4. Bespoke Solutions

We work with architects/designers to make quality lighting. Smooth process, great results.

相关新闻

The process of hardware processing 3

The process of hardware processing 3

May 07,2025

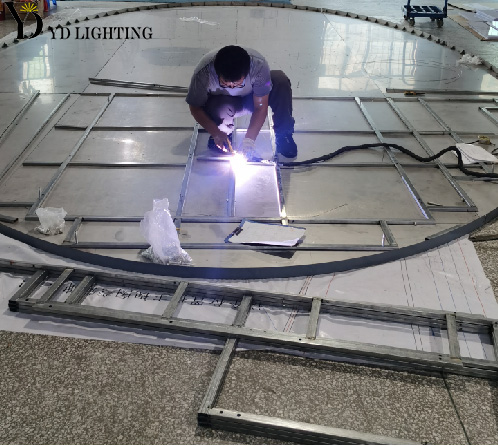

In the field of lighting hardware processing, craftsmen always uphold the attitude of striving for perfection, and every step demonstrates their ultimate pursuit of detail. During the material selection stage, craftsmen use calipers to precisely measure the thickness of metal materials multiple times. Any slight unevenness on the surface cannot escape their sharp eyes. Even the tiniest burrs will be carefully polished and processed to ensure that the materials are of the highest quality.

When it comes to the forming and processing stage, the assembly of stamping dies must meet the standard of being perfectly aligned. When bending metal, craftsmen strictly control the angular error within an extremely small range. Even a deviation of half a degree will prompt immediate rework and adjustment, all to create neat and aesthetically pleasing shapes for components such as lamp shades and brackets.

The process of hardware processing 2

The process of hardware processing 2

May 07,2025

In the field of lighting hardware processing, craftsmen always uphold the attitude of striving for perfection, and every step demonstrates their ultimate pursuit of detail. During the material selection stage, craftsmen use calipers to precisely measure the thickness of metal materials multiple times. Any slight unevenness on the surface cannot escape their sharp eyes. Even the tiniest burrs will be carefully polished and processed to ensure that the materials are of the highest quality.

When it comes to the forming and processing stage, the assembly of stamping dies must meet the standard of being perfectly aligned. When bending metal, craftsmen strictly control the angular error within an extremely small range. Even a deviation of half a degree will prompt immediate rework and adjustment, all to create neat and aesthetically pleasing shapes for components such as lamp shades and brackets.

The process of hardware processing 1

The process of hardware processing 1

May 07,2025

In the field of lighting hardware processing, craftsmen always uphold the attitude of striving for perfection, and every step demonstrates their ultimate pursuit of detail. During the material selection stage, craftsmen use calipers to precisely measure the thickness of metal materials multiple times. Any slight unevenness on the surface cannot escape their sharp eyes. Even the tiniest burrs will be carefully polished and processed to ensure that the materials are of the highest quality.

When it comes to the forming and processing stage, the assembly of stamping dies must meet the standard of being perfectly aligned. When bending metal, craftsmen strictly control the angular error within an extremely small range. Even a deviation of half a degree will prompt immediate rework and adjustment, all to create neat and aesthetically pleasing shapes for components such as lamp shades and brackets.